To provide the best results to their customers, BMG has always tried to provide services and to produce the best product, therefore the latest technology is one of the reference BMG to provide the best production results. By using machines made in Europe that produces a full 24 hours of BMG is able to produce a production capacity of up to 21.000 m² glass in a day. Not only is it to ensure the quality of the output, a special team of Quality Control BMG always conduct an examination of its products.

To provide the best results to their customers, BMG has always tried to provide services and to produce the best product, therefore the latest technology is one of the reference BMG to provide the best production results. By using machines made in Europe that produces a full 24 hours of BMG is able to produce a production capacity of up to 21.000 m2 glass in a day. Not only is it to ensure the quality of the output, a special team of Quality Control BMG always conduct an examination of its products.

BMG Laminated Glass is produced by placing a Polyvinyl Butyral (PVB interlayer) between two or more layers of glass, and is then bonded together under elevated temperature and pressure. The PVB interlayer is of high strength. When laminated glass is subjected to external impact, the PVB interlayer can absorb most of the impact force. Even when the glass is broken, the broken glass pieces are still attached to the PVB interlayer as a whole without falling apart. It is regarded as real safety glass

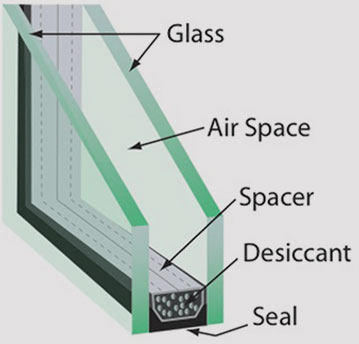

IGU is the assembly of two pieces of glass, adheres firmly between a desiccants (drying agent) filled aluminum spacer bar and sealed permanently along its perimeter with a secondary silicone sealant.

The Primary function of IGU is to reduce heat and thermal transfer between building interior and exterior. Reduced heat and thermal would result in a more efficient cooling and heating, which in turn saves power and electricity.

IGU can be built using tempered glass and/or Laminated Glass to achieve proper strenght and safety requirement.

BMG Ceramic Frit glass offers building designers a variety of options involving safety, beauty, originality and functionality. Creating exciting and different ways to customize exterior and interior glass for a truly one of a kind effect maintaining the solar control and safety standards.

This technique consists of applying a coat of ceramic frit over the glass surface by means of a screen frame and then drying it in with an infrared furnace before tempering. The screened glass is then tempered in the same way as glass without paint.